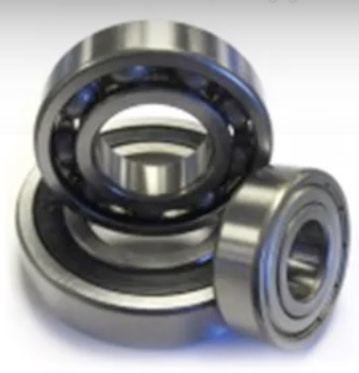

A rolled ball screw assembly is metallic, usually steel, and it is made of a threaded rod called the screw in addition to an internally threaded nut whose helical grooves match those of the screw. Inside the grooves and contained within the nut are many small ball bearings typically made of chrome steel. The balls provide smooth motion down the screw as they circulate through the nut. Read More…

Del-Tron Precision, Inc. produces and supplies various automated equipment, such as ball screw actuators. Our engineers have designed our ball screws to offer accuracy that is unparalelled by competitors.

When it comes to ball screws, no one does them better! We offer same day shipping to ensure that your product will be sent to you as soon as possible in order to keep your business moving smoothly.

Wedin International specializes in ball screws of various types and assemblies. We also offer 24-hour product repair. Wedin International provides several industries and applications with high-quality products and services. Wedin covers all types of motion control parts for any application. Call today, we would be glad to discuss your needs and welcome the opportunity in working with you.

More Rolled Ball Screw Manufacturers

Deflectors or return systems retain the balls and keep them circulating through the nut. Rolled ball screws are up to 90% efficient when used with a motor. They are fairly precise with accuracies of several thousandths of an inch per foot and may be custom made. Rolled ball screws are used by many industries for the precise control they offer including the aerospace, computer, electronic, automotive and medical industries.

Ball screws are also frequently used in manufacturing processes and are common in robots, automated assembly lines, material handling equipment, conveyors, machine tools, fly by wire control, precision assembly equipment and more.

There are three main ways that the threads on ball screws are fabricated: through grinding, milling and rolling. Milled screws are the result of machining that uses tools to cut and remove selected material. Ground screws are first machined to their gross shape then case hardened and ground on machines with abrasive materials that spin at rapid speeds. This process allows the resulting ball screws to withstand high temperatures that would otherwise distort the shape and efficiency of the screw.

Ground screws are the most precise option but are also more expensive. Rolled ball screws are made from blank metal workpieces that are cold rolled into the screw shaft. Rolled ball screws are made by using movable and fixed forming dies. A servo maintains the correct pressure and compensates for any changes in screw diameter as the dynamically positioned movable die forms the screw.

The linear axis of the screw, however, cannot be guaranteed past certain points; the rod may not be perfectly cylindrical. Because there is no grinding, machining costs decrease, which makes rolled screws an affordable choice for many manufacturers. After the rolled ball screw shaft is fabricated, the nut must be added to complete the assembly.

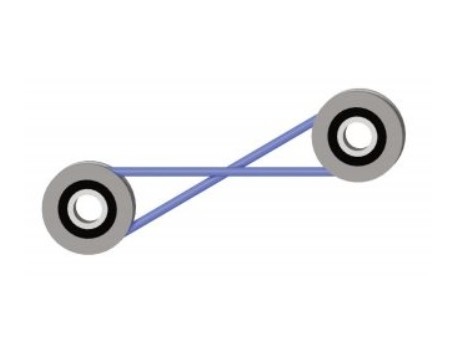

The screw and nut do not twist together like a nut and bolt do; instead, the balls spin around the grooves between the threading and allow the nut to slide.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services