Lead screws are metal bars with threads and a threaded nut. A lead screw may also be referred to as a translating screw or a power screw. This specific mechanical linear actuator transforms rotational motion into linear motion. A lead screw’s shaft and nut threads must slide for it to work. The nut moves along linearly in a lead screw as a rotational action turns the screw. As a result, the motion is changed from rotary to linear.Read More…

Del-Tron Precision, Inc. produces and supplies various automated equipment, such as ball screw actuators. Our engineers have designed our ball screws to offer accuracy that is unparalelled by competitors.

When it comes to ball screws, no one does them better! We offer same day shipping to ensure that your product will be sent to you as soon as possible in order to keep your business moving smoothly.

Wedin International specializes in ball screws of various types and assemblies. We also offer 24-hour product repair. Wedin International provides several industries and applications with high-quality products and services. Wedin covers all types of motion control parts for any application. Call today, we would be glad to discuss your needs and welcome the opportunity in working with you.

More Lead Screw Manufacturers

Lead screws are essential mechanical components that convert rotary motion into linear motion with high precision and reliability. Used extensively in a wide range of mechanical and automation systems, lead screws enable both vertical and horizontal movements, making them invaluable for various industrial and commercial applications. When supporting heavier loads or requiring precise linear guidance, lead screws are often paired with linear glides for enhanced stability and reduced friction. Depending on user requirements, lead screws can be mortised (fixed into a structure) or operated manually for tasks that demand fine adjustment.

Compared to ball screws, lead screws offer a more affordable solution, especially in low-power, moderate- to medium-duty applications. Their cost-effectiveness, versatility, and lower maintenance requirements make them an attractive choice for engineers, designers, and automation professionals seeking efficient linear actuation solutions.

Types of Lead Screws

Selecting the right type of lead screw is critical for achieving optimal performance in specific applications. The three primary types—square thread lead screws, acme thread lead screws, and buttress thread lead screws—differ in geometry, load capacity, efficiency, and suitability for various use cases.

Square Thread Lead Screws

The defining feature of the square thread lead screw is its square-shaped threads, where the flanks run parallel to the screw’s axis. This geometry results in a 0° thread angle, eliminating radial or bursting pressure on the nut. In practical terms, there is minimal radial strain on the assembly, reducing friction and significantly improving energy efficiency and operational lifespan.

Square thread lead screws are renowned for their high load-bearing capacity and are ideal for power transmission and heavy-duty motion transfer applications. Because of their efficiency, they can handle higher loads for a given size or reduce the required motor size—an important factor for energy-conscious machine design. Common use cases include jackscrews, heavy-duty clamping systems, presses, and precision machinery such as lathes.

Despite their advantages, square thread lead screws can be challenging and costly to manufacture due to the need for single-point cutting tools and precise machining. However, their superior efficiency, intrinsic strength, and long service life make them a preferred choice for demanding industrial and mechanical environments.

Key Benefits of Square Thread Lead Screws:

- Maximum load-bearing capability for a given size

- Minimal friction and wear for prolonged service life

- Superior efficiency compared to other thread types

- Ideal for high-load, high-precision applications

Acme Thread Lead Screws

Acme thread lead screws are characterized by their trapezoidal thread profile, typically featuring a 29° thread angle. This unique profile offers a balance between ease of manufacture and mechanical performance. The angled flanks of acme threads allow for more straightforward and cost-effective production, often utilizing multi-point cutting tools.

While acme threads introduce slightly more friction than square threads, they compensate with increased load-bearing capacity, robustness, and resistance to wear. Acme thread lead screws are commonly found in linear actuators, machine tools, clamps, valve stems, and bench vices. Their versatility makes them a popular choice for both industrial automation and general-purpose linear motion systems.

There are three main types of acme threads—general purpose, centralizing, and stub acme threads—each optimized for specific mechanical requirements. For instance, centralizing acme threads are designed to minimize backlash, while stub acme threads are suited for applications with space limitations or where a shallower thread is required.

Why Choose Acme Thread Lead Screws?

- Excellent balance of strength and manufacturability

- Available in various profiles for specific applications

- Widely used in machine tools, actuators, and vices

- Enhanced load capacity compared to standard threads

- Cost-effective for medium-duty linear actuation

Looking for more details on acme threaded rods? Explore our comprehensive resources and supplier listings for detailed specifications, pricing, and application guidance.

Buttress Thread Lead Screws

Buttress thread lead screws feature a unique triangular thread profile optimized for unidirectional load applications. The design incorporates a wide base and robust teeth, giving buttress threads approximately twice the shear strength of square threads—making them ideal for high-force, single-direction actuation.

Buttress thread screws are commonly used in heavy-duty presses, vertical lifts, jacks, and specialized turning and milling equipment. Their geometry efficiently transmits power and withstands heavy axial loads in one direction. However, they are not suitable for applications requiring bidirectional load handling, as their strength and efficiency are optimized for one-directional force.

Thanks to their simplified machining and robust design, buttress threads offer manufacturing advantages similar to acme threads, while delivering exceptional performance and reliability in demanding environments.

Advantages of Buttress Thread Lead Screws:

- Superior shear strength for heavy unidirectional loads

- Efficient power transmission in presses and lifting equipment

- Cost-effective manufacturing compared to square threads

- Durable performance in high-force, single-direction applications

Lead Screw Applications: Where Are Lead Screws Used?

Lead screws are widely recognized for their versatility, reliability, and adaptability across a broad spectrum of industries and mechanical systems. Whether you're designing automation solutions, precision medical equipment, or robust construction tools, understanding the diverse applications of lead screws is key to making an informed purchasing decision.

- Fluid-handling equipment: Lead screws enable tight fittings and precision control, ensuring minimal leakage in pumps, valves, and dosing systems.

- Heavy lifting and industrial machinery: Their strength and load-bearing capacity make lead screws the go-to choice for jacks, presses, and vertical lifts. Metallic nuts are typically used to handle higher stress environments.

- Instrumentation and laboratory equipment: For applications that demand smooth, accurate, and maintenance-free operation—such as microscopes, optical devices, and automated analyzers—lead screws deliver exceptional linear motion control.

- Linear actuators: Lead screws convert rotary motion to linear displacement in electric actuators, robotics, and CNC systems, providing precise and repeatable positioning.

- Machine slides and vices: Machine tools, presses, and mechanical vices rely on lead screws for robust, controlled motion and secure clamping.

- Medical devices: Precision lead screws are used in surgical tables, diagnostic imaging systems, and infusion pumps for reliable, precise movement.

- 3D printers and automation: In additive manufacturing and automated assembly, lead screws ensure accurate layer deposition and component positioning.

- Automotive and aerospace: Used in seat actuators, control surfaces, and other linear motion subsystems requiring high reliability and durability.

Key Benefits and Advantages of Lead Screws

When considering options for linear motion systems, lead screws offer several distinct advantages over competing technologies. Here’s why they continue to be a top choice for engineers and manufacturers worldwide:

- Highly precise measurements: Low-pitch lead screws are integral in machine tool applications, providing exceptionally accurate and repeatable motion—critical for CNC machinery, metrology, and high-precision assembly.

- Vertical operation efficiency: Lead screws function efficiently in vertical orientations, often featuring self-locking capabilities to prevent back-driving or unintended movement—a valuable safety feature in lifting and hoisting applications.

- Self-locking mechanisms: Many lead screws are inherently self-locking, eliminating the need for additional braking systems and enhancing safety and reliability in static or load-holding positions.

- Compact and space-saving design: With fewer parts than ball screws or rack-and-pinion systems, lead screws allow for more compact assemblies and streamlined mechanical layouts.

- Quiet, low-maintenance operation: Lead screws generate less noise during operation and typically include self-lubricating surface treatments, reducing the need for frequent lubrication and minimizing downtime.

- Cost-effectiveness: Their simpler design and manufacturing process often result in lower purchase and maintenance costs—ideal for budget-conscious projects and moderate-duty applications.

- Customization potential: Lead screws are available in a wide range of diameters, pitches, materials (such as stainless steel, bronze, or plastic), and coatings to suit specific environmental and performance requirements.

- Corrosion resistance: With proper material selection and surface treatments, lead screws can withstand harsh environments, making them suitable for outdoor, marine, or chemical processing applications.

Questions to Ask When Evaluating Lead Screw Solutions:

- What load capacities and duty cycles are required for your application?

- Is precise, backlash-free motion essential for your system’s performance?

- Will the lead screw operate in a corrosive or harsh environment?

- Do you need a self-locking feature to prevent back-driving?

- What level of maintenance and operational noise is acceptable for your application?

- Are custom diameters, pitches, or materials necessary?

Lead Screw Selection: Factors to Consider for Optimal Performance

Choosing the right lead screw is crucial for maximizing system efficiency, reliability, and lifespan. Here are some of the most important factors buyers and engineers should evaluate when specifying lead screws for a new system or retrofit:

- Load requirements: Carefully assess the maximum static and dynamic loads your application will encounter. Oversizing or undersizing the screw may lead to premature wear or operational failure.

- Speed and duty cycle: High-speed applications may require specialized thread profiles or advanced materials to minimize heat generation and wear. Consider the expected duty cycle and frequency of use.

- Backlash and precision: For applications requiring high positioning accuracy or minimal play, select screws with tight manufacturing tolerances and compatible anti-backlash nuts.

- Material compatibility: Choose lead screws and nuts made from materials resistant to wear, corrosion, and environmental hazards specific to your use case.

- Lubrication and maintenance: Determine if your application can benefit from self-lubricating coatings or materials, or if regular lubrication schedules are feasible.

- Thread profile selection: Match the thread geometry (square, acme, or buttress) to the load, directionality, and efficiency requirements of your system.

- Environmental conditions: Take into account temperature extremes, humidity, exposure to chemicals, or potential for debris ingress, and select protective finishes or enclosed designs as needed.

- Cost and availability: Balance upfront costs with expected lifespan, operational efficiency, and maintenance requirements to determine the most cost-effective solution.

Looking for expert advice on selecting the optimal lead screw for your automation project, CNC retrofitting, or medical device design? Contact our team or browse our directory of lead screw manufacturers for personalized guidance, technical specifications, and competitive quotes.

Choosing the Right Lead Screw Manufacturer and Supplier

Partnering with a reputable lead screw manufacturer ensures you receive high-quality components tailored to your exact requirements. To secure the best results when purchasing lead screws, it’s essential to evaluate multiple suppliers, compare technical capabilities, and review customer support offerings.

- Compare at least five suppliers using our lead screw companies directory for side-by-side insights on specialization, certifications, and production capacity.

- Access each manufacturer’s business profile page to understand their areas of expertise, product range, and quality assurance processes.

- Use our website previewer to quickly assess each company’s website, certifications, and lead times.

- Leverage our streamlined RFQ (Request for Quote) form to contact multiple manufacturers with a single inquiry, saving time and ensuring competitive pricing.

- Request samples or technical datasheets to evaluate product quality, dimensional accuracy, and suitability for your application.

- Investigate after-sale technical support, customization options, and warranty terms to ensure long-term satisfaction and operational reliability.

Ready to source high-performance lead screws for your next project?

Start by exploring our vetted list of lead screw manufacturers and request a quote today. For technical questions, application engineering, or custom orders, reach out to our support team for fast, expert assistance.

Frequently Asked Questions About Lead Screws

What is the main difference between lead screws and ball screws?

Lead screws use direct sliding contact between the screw and nut threads, while ball screws utilize ball bearings to reduce friction and increase efficiency at higher speeds. Lead screws are generally quieter, more affordable, and better for self-locking applications, while ball screws excel in high-precision, high-speed, or heavy-duty environments.

Are lead screws suitable for precision automation and CNC applications?

Yes, especially in scenarios where moderate speeds and high accuracy are required. Lead screws with anti-backlash nuts and tight manufacturing tolerances are a popular choice for CNC machines, 3D printers, and medical automation.

Can lead screws operate in harsh or corrosive environments?

Absolutely. By selecting appropriate materials (such as stainless steel or corrosion-resistant coatings), lead screws can be specified for outdoor, marine, chemical, or food-grade environments.

What maintenance do lead screws require?

Many lead screws are self-lubricating or require only periodic maintenance. However, operating conditions, load, and duty cycle will dictate the optimal maintenance schedule. Always consult the manufacturer’s recommendations for best practices.

Need more guidance?

Visit our lead screw resource center for technical articles, selection tools, and industry best practices.

Conclusion: Unlock Reliable Linear Motion with Lead Screws

Lead screws stand out as a versatile, economical, and reliable choice for linear motion systems across diverse industries. Their unique combination of precision, load-handling ability, self-locking features, and low maintenance make them an excellent solution for everything from industrial automation and medical devices to laboratory equipment and manufacturing machinery. By understanding the various types of lead screws, their benefits, applications, and decision factors, engineers and purchasing specialists can confidently specify the best solution for their needs.

Ready to take the next step? Browse our lead screw manufacturers and request a quote or technical consultation today. Empower your machinery with the reliability and performance of high-quality lead screws.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

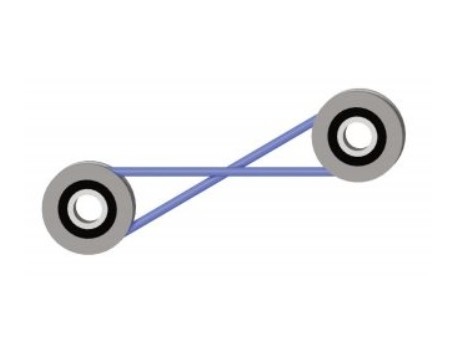

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services