Ball screw nuts change torque into thrust without rotating themselves. The ball bearings rotate instead and the nut housing remains radially static as it slides on the shaft. Ball screw nuts can be made from plastic or metal; the shaft of the ball screw is machined from steel. Read More…

Del-Tron Precision, Inc. produces and supplies various automated equipment, such as ball screw actuators. Our engineers have designed our ball screws to offer accuracy that is unparalelled by competitors.

When it comes to ball screws, no one does them better! We offer same day shipping to ensure that your product will be sent to you as soon as possible in order to keep your business moving smoothly.

Wedin International specializes in ball screws of various types and assemblies. We also offer 24-hour product repair. Wedin International provides several industries and applications with high-quality products and services. Wedin covers all types of motion control parts for any application. Call today, we would be glad to discuss your needs and welcome the opportunity in working with you.

More Ball Screw Nut Manufacturers

Ball Screws: Precision Linear Motion Solutions for Industrial Applications

Ball screws are critical components in modern motion control and linear automation systems, frequently integrated with linear slides and linear actuators to deliver smooth, precise, and repeatable linear motion. Their advanced engineering enables them to convert rotational motion into linear displacement with minimal friction, making them ideal for demanding environments where accuracy, efficiency, and durability are paramount.

What Is a Ball Screw and How Does It Work?

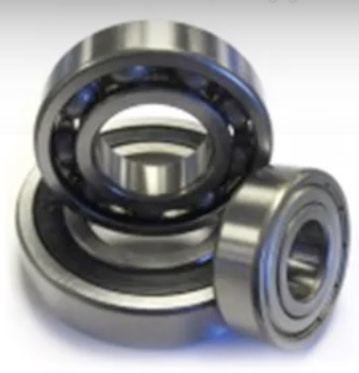

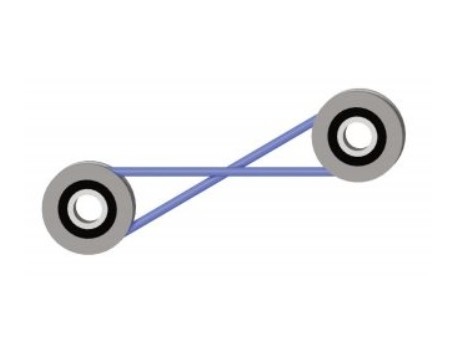

A ball screw consists of a threaded screw shaft and a matching nut containing numerous recirculating ball bearings. As the screw or nut rotates, these hardened steel balls roll along the helical tracks, effectively reducing friction and providing exceptionally efficient mechanical conversion. This rolling contact drastically minimizes energy loss compared to traditional lead or acme screws, resulting in mechanical efficiencies as high as 90%—a crucial advantage for motorized systems requiring high duty cycles or rapid actuation.

When evaluating ball screw assemblies, engineers and procurement professionals consider several factors to ensure optimal performance and longevity. Key ball screw selection criteria include:

- Desired lifespan and maintenance intervals

- Operating environment, including temperature, humidity, and exposure to contaminants

- Required torque and output force

- Backlash (axial play) and positional accuracy requirements

- Contamination resistance and lubrication needs

Industries such as aerospace, semiconductor manufacturing, medical device engineering, automotive, electronic assembly, and precision manufacturing rely on ball screws for their unmatched combination of efficiency, load capacity, and positioning repeatability.

Key Benefits of Ball Screws in Motion Control Systems

Why choose ball screws over other linear motion systems or lead screws? The answer lies in their many performance advantages:

- High Efficiency: Rolling ball contact drastically reduces friction, lowering energy consumption and enabling rapid, accurate movements in automated machinery.

- Precision and Repeatability: Manufactured to tight tolerances, ball screws deliver micron-level positional accuracy, essential for CNC machines, robotics, and semiconductor wafer handling.

- Long Service Life: With proper lubrication and sealing, ball screws can achieve extremely long operating lives, reducing maintenance costs and downtime.

- High Load Capacity: The ball bearings distribute axial loads evenly, allowing for higher load ratings compared to similarly sized acme or lead screws.

- Backlash Minimization: Preloaded ball nuts and anti-backlash designs enhance system stiffness and positioning stability.

- Customizable for Application Needs: Available in a range of sizes, leads, and accuracy grades—including rolled, ground, and milled variants.

Curious about which ball screw design is best for your automation project? Contact our engineering team or continue reading to discover how various ball screw types deliver tailored performance in diverse applications.

Industrial and Commercial Applications for Ball Screws

Ball screw assemblies are essential in countless automation and precision positioning applications. Some of the most common uses include:

- Medical Devices & Diagnostic Equipment: Precision ball screws ensure smooth, reliable motion in imaging systems, robotic surgery platforms, and laboratory automation.

- Material Handling Equipment: Conveyors, pick-and-place robots, and automated storage systems leverage ball screws for efficient load transfer and accurate positioning.

- Machine Tools and CNC Equipment: High-precision ground ball screws are foundational in CNC lathes, milling machines, 3D printers, and EDM machines for consistent part accuracy.

- Semiconductor Fabrication: Cleanroom-compatible ball screws provide contamination control and precise wafer handling in chip manufacturing processes.

- Aerospace and Defense: Ball screws are used in fly-by-wire actuation, missile guidance, and satellite deployment mechanisms, where reliability and precision are mission-critical.

- Robotics and Automation: Articulated robots, gantry systems, and assembly lines rely on ball screws for repeatable, high-speed linear actuation and payload manipulation.

Are you exploring ball screw solutions for your next automation or robotics project? Request a quote or compare ball screw specifications using our interactive product selector tool.

Understanding Ball Screw Construction and Manufacturing Methods

The construction of a ball screw assembly directly impacts its accuracy, load rating, and suitability for specific environments. There are three primary manufacturing methods:

- Milled Ball Screws: Milled variants are created by cutting helical grooves into the screw shaft using precise machining tools. This method offers good cost-effectiveness for applications where ultra-high precision is not required.

- Rolled Ball Screws: In the rolling process, a series of dies progressively shapes a metal blank into the desired screw geometry. Rolled ball screws are economical, suited for moderate-precision applications and high-volume production.

- Ground Ball Screws: For the highest accuracy and smoothness, ground ball screws are first machined, then hardened and finish-ground to exacting tolerances. These are preferred for demanding applications like CNC machining, metrology, and medical imaging equipment.

The choice of manufacturing method depends on required lead accuracy, backlash, and cost constraints. Need help determining the right ball screw grade for your system? Consult our technical resources or speak with a motion control specialist for application-specific recommendations.

Ball Nut Designs: External vs Internal Ball Return Systems

Ball nuts play a crucial role in the performance and longevity of a ball screw assembly. There are two main types of ball return systems:

- External Ball Return: This design incorporates short, curved tubes (return pipes) on the outside of the nut. As balls circulate through the helical grooves, these return paths guide them from one end of the nut to the other, ensuring continuous recirculation. External returns are often used in high-load or long-travel applications.

- Internal Ball Return (Deflector Type): Internal deflectors are integrated within the nut body, redirecting balls back to the starting point. This design offers a more compact profile and reduces the risk of external contamination, making it ideal for cleanroom, medical, or compact machinery applications.

Choosing the right ball nut design affects not only the size and mounting options but also the maintenance requirements and overall reliability of your linear motion system.

Ball Screws vs. Lead Screws and Acme Screws: What's the Difference?

While ball screws, acme screws, and lead screws all provide linear motion, their operating principles and suitability for different tasks vary significantly:

- Ball Screws: Utilize recirculating ball bearings to minimize friction and maximize efficiency. Best for high-precision, high-duty-cycle, and automated applications.

- Lead Screws & Acme Screws: Rely on direct sliding contact between the screw and nut threads. These designs are simpler and easier to manufacture, and can offer self-locking capabilities. However, they generate higher friction and wear, making them less efficient and less suitable for rapid or continuous motion.

Key Considerations:

- Efficiency: Ball screws are up to 90% efficient; lead screws are typically 20–40% efficient.

- Backlash: Ball screws can be preloaded for minimal backlash; lead screws often exhibit greater play.

- Cost: Ball screws generally cost more upfront but offer lower total cost of ownership thanks to reduced energy consumption and maintenance.

- Self-locking: Lead screws may hold position without power, while ball screws typically require a brake or counterweight in vertical applications.

If you're deciding between a ball screw and a lead screw for your project, review our comprehensive ball screw vs. lead screw comparison guide to weigh the pros and cons for your specific use case.

How to Select the Right Ball Screw for Your Application

Choosing the optimal ball screw involves careful consideration of application-specific requirements. Here are some important steps and decision factors:

- Define Load and Speed Requirements: Determine the maximum dynamic and static loads, as well as the required travel speed and acceleration. This will inform the appropriate screw diameter and lead.

- Establish Positional Accuracy and Repeatability Needs: Identify the required level of precision and allowable backlash for your system. Applications such as CNC machining or medical imaging may demand ground ball screws with micron-level accuracy.

- Assess Environmental Conditions: Consider exposure to dust, moisture, chemicals, and temperature extremes. Specify appropriate materials, coatings, seals, and lubricants as needed.

- Evaluate Mounting and Integration Constraints: Ensure compatibility with linear actuators, bearings, and support blocks. Factor in installation space, alignment tolerances, and ease of maintenance.

- Review Cost vs. Performance Trade-offs: Balance initial investment with long-term operating costs, maintenance intervals, and expected system lifespan.

Use our ball screw sizing calculators and application engineering support to optimize your selection. Not sure where to start? Ask, "What ball screw size do I need for a 500 kg load at 1 m/s travel speed?" Our experts can help you make a data-driven decision.

Maintenance and Longevity: Maximizing Ball Screw Service Life

To ensure maximum reliability and performance, regular maintenance of ball screw assemblies is essential. Best practices include:

- Lubrication: Use manufacturer-recommended lubricants to minimize wear and prevent corrosion. Automatic lubrication systems can further extend service intervals.

- Contamination Control: Install wipers, seals, or bellows to prevent ingress of dust, chips, or fluids, especially in harsh industrial or manufacturing environments.

- Inspection and Adjustment: Periodically check for signs of wear, abnormal noise, or increased backlash. Adjust preload or replace worn components as needed.

- Proper Installation: Ensure alignment, support, and mounting according to OEM guidelines to prevent misload and premature failure.

For a detailed guide on extending the life of your ball screw system, download our maintenance checklist or schedule a preventative maintenance consultation.

Frequently Asked Questions About Ball Screws

- What are the key differences between rolled and ground ball screws?

Rolled ball screws are formed by rolling dies, making them cost-effective for moderate-precision use. Ground ball screws undergo a grinding process after machining and hardening, offering superior accuracy and surface finish for high-precision applications. - How do I minimize backlash in my ball screw assembly?

Use preloaded ball nuts, select high-precision (ground) screws, and ensure proper installation to reduce axial play and improve repeatability. - Can ball screws handle vertical loads?

Yes, but ball screws are not self-locking and may require a brake or counterweight in vertical applications to prevent back-driving when power is off. - Which industries benefit most from ball screws?

Aerospace, medical, semiconductor, electronics, automotive, and industrial automation sectors all leverage ball screws for their efficiency and accuracy. - How often should I lubricate my ball screw?

Frequency depends on load, speed, and environment, but regular lubrication is essential. Refer to manufacturer guidelines or consult our technical team for a maintenance schedule.

Explore Ball Screw Solutions and Resources

Ready to take the next step? Browse our ball screw product catalog for detailed specifications, 3D CAD models, and pricing information. Connect with our engineering support for custom ball screw design or application assistance.

Conclusion: Why Choose Ball Screws for Linear Motion?

In summary, ball screws deliver unparalleled precision, efficiency, and reliability for a wide range of linear motion and automation applications. Whether you're upgrading existing equipment, designing a new machine, or seeking ways to improve throughput and reduce energy consumption, ball screws offer a proven solution that meets the highest industry standards.

Still have questions? Ask us, “What is the best ball screw for my CNC machine?” or “How do I prevent ball screw failure in harsh environments?” Our team is ready to help you achieve optimal performance for your unique application needs.

For more on ball screws, linear actuators, and advanced motion control technology, subscribe to our newsletter and stay informed on the latest innovations in industrial automation.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services