Acme threading is superior to square thread in many ways, offering a much more effective design for generating power for motion. Additionally, compared to V-shaped threads, Acme threads give additional strength due to their 29-degree angle. As a result, Acme threaded rod is frequently used in industrial applications, such as presses, milling machines, and more, since it can produce strong torque and power transmission. The thread helix comes in left- and right-handed varieties or directions. However, right-hand threads are the most prevalent. Read More…

Del-Tron Precision, Inc. produces and supplies various automated equipment, such as ball screw actuators. Our engineers have designed our ball screws to offer accuracy that is unparalelled by competitors.

When it comes to ball screws, no one does them better! We offer same day shipping to ensure that your product will be sent to you as soon as possible in order to keep your business moving smoothly.

Wedin International specializes in ball screws of various types and assemblies. We also offer 24-hour product repair. Wedin International provides several industries and applications with high-quality products and services. Wedin covers all types of motion control parts for any application. Call today, we would be glad to discuss your needs and welcome the opportunity in working with you.

More Acme Threaded Rod Manufacturers

The most popular and best for general fastening purposes are single-start threads. Due to the thread's smaller helix angle, they provide greater resistance to loosening than multi-start threads. However, multi-start threads with multiple leads are used when quick disassembly is required.

Types of Acme Threads

When producing Acme threaded rods, three different types of threads are employed, these include:

- General Purpose (G)

- Centralizing (C)

- Stub Acme

General Purpose (G)

Generally, the common three-dimensional rod is used for machine tools, mechanisms, and valves. Every thread uses a trapezoidal thread form. They offer excellent strength and simplicity in manufacturing. Standardized variations include left-hand, multiple-start, and self-centering threads (which are less likely to bind when subjected to lateral forces). The Acme threaded rods replaced the triangular thread because they were significantly more effective at generating power for motion. A general-purpose rod is a looser fit and works better in dusty conditions.

Centralizing (C)

Except for the major diameter of both the internal and external screw threads having a limited clearance and being widely utilized for feed screws, centralizing Acme screw threads have the same thread form as general-purpose Acme threads. In addition, the constrained clearance permits a bearing at the major diameter of the thread to maintain thread axis alignment, reducing component sagging and wedging on the flanks.

Stub Acme

Stub Acme threads have been truncated, shrunk, or "stubbed" with numerous allowed variants for usage in tighter places.

How are Acme Threaded Rods Made?

Due to their durability, affordability, weight, and strength, steel and aluminum are two of the more popular raw materials in manufacturing Acme threaded rods. For applications where the rod is often exposed to corrosive elements, stainless steel is commonly used due to its inherent corrosion resistance. On the other hand, heavy-duty steel may be required in other circumstances to support big loads. Therefore, the thread rolling machine mass-produces threaded rods of a standard diameter and grade.

First, the round bar is passed through two hardened steel rollers to imprint the thread onto the bar. The incredibly high pressures applied by these rollers, which are spaced apart precisely and rotated perpendicular to the direction the round bar is being passed through them, transform the round bar into a threaded bar. Next, the round bar is pushed through rollers to imprint the thread into the surface in this largely automated process. Finally, after being sawed to size, the threaded bar's edges are beveled to create a smooth, usable, completed surface.

Applications of Acme Threaded Rods

Industrial applications that require significant torque and power transmission use Acme rods frequently. Acme thread is made to support large loads easily. Acme rods have the following applications:

- CNC drive systems

- Lathes

- Milling machines

- Presses

- Lead screws

Compared to ordinary threaded rods, Acme screws have significantly improved wear characteristics, load capacities, and tolerances. Acme threaded rods perform better in dirt and debris areas because of their thicker and wider threads. For controlled motions on conveyors, jacks, testing equipment, and aircraft flaps, long-length Acme threads are used. Valve stems, hose couplings, pressure cylinder bonnets, steering systems, and camera lens movement all require short-length threads.

Benefits of Acme Threaded Rods

There are several benefits of Acme threading over the ordinary threaded rod. Among the advantages of Acme threaded rods are:

- Compared to other possibilities, Acme threads use a 29-degree angle, resulting in wider and stronger threading.

- Compared to ordinary threaded rods, Acme rods have significantly better wear characteristics, load capacities, and tolerances.

- When there is dirt and debris present, thicker Acme threading performs better.

- General-purpose Acme threads are made to function interchangeably at various grades.

- The shape of the Acme thread is easier to machine.

- The Acme thread has a wider base making it robust.

- The Acme thread allows the use of the split nut.

- They are relatively economical.

Drawbacks of Acme Threaded Rods

- Acme threads are less efficient than square threads due to increased friction, and they also provide some radial pressure on the nut (angular offset from square).

- They are susceptible to backlash, which causes them to wear out more quickly and become jammed up over time, leading to incorrect alignment.

- Slower motion

- Hard to support long spans

- They lose precision over time.

Choosing the Right Acme Threaded Rods Company

To make sure you have the most positive outcome when purchasing Acme Threaded Rods from an Acme Threaded Rods Supplier, it is important to compare at least 4 Companies using our list of Acme Threaded Rods companies. Each Acme Threaded Rods Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Acme Threaded Rods company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Acme Threaded Rods businesses with the same message.

Ball Bearings

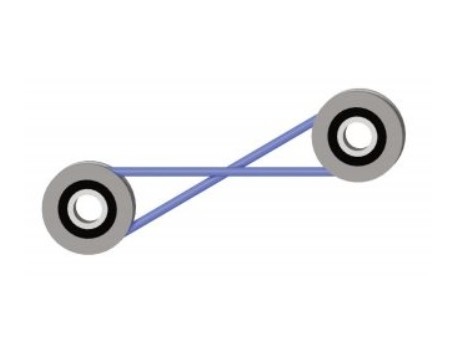

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services